Helical Reducer

Call for a Quote

+54 3564 443823

All Services

Features

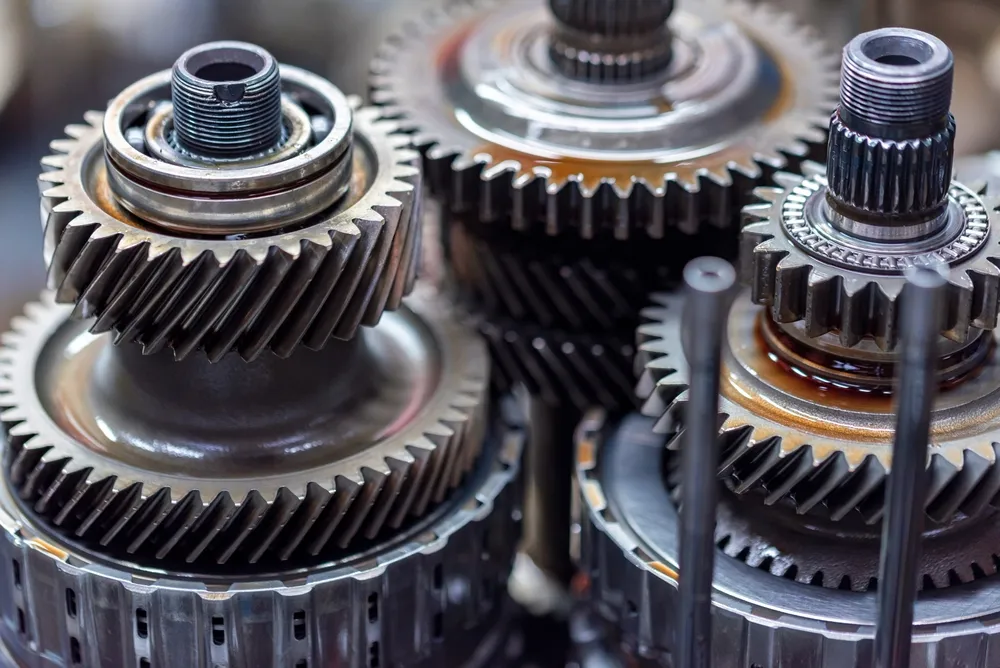

Helical Gear Design

The gears in a helical reducer are cut at an angle to the face of the gear. Unlike straight-cut spur gears, helical gears have teeth that are set at an angle to the gear axis, providing a gradual engagement of the gears. This design allows for more tooth surface contact, which distributes the load more evenly.

Smooth and Quiet Operation

The gradual engagement of helical gears results in a smoother and quieter operation compared to spur gears. This makes helical reducers ideal for applications where noise reduction is important.

High Load Capacity

Due to the increased surface contact between teeth, helical gears can carry more load than spur gears of the same size. This makes helical reducers suitable for high-load applications.

Increased Efficiency

The efficiency of helical reducers is generally higher than that of spur gear reducers, particularly at higher speeds. This is due to the reduced friction and heat generated by the smoother operation of helical gears.

Versatility

Helical reducers can be used in a variety of applications and industries, including automotive, industrial machinery, conveyors, and material handling systems.

Durability

The enhanced load distribution and reduced stress on individual teeth contribute to the longevity and durability of helical reducers.

Axial Thrust

One characteristic of helical gears is that they generate axial thrust, a force parallel to the axis of rotation. This requires helical reducers to have bearings that can accommodate these forces, adding to the design complexity.

Compact Design

Compared to other types of gear systems with similar power transmission capabilities, helical reducers often have a more compact footprint.

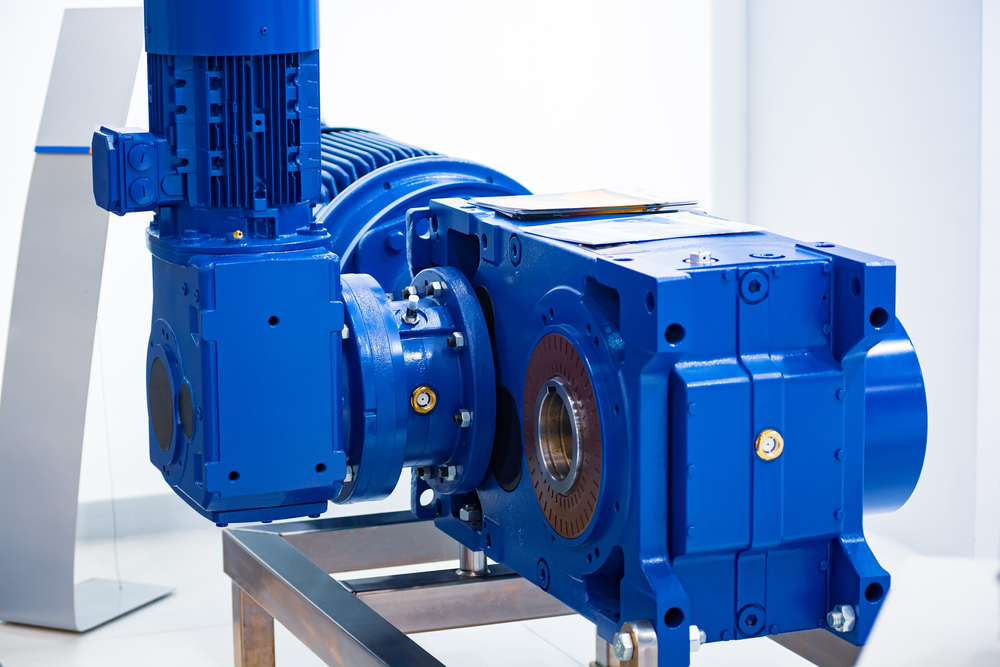

High precision low noise hypoid Reduction Gearbox reducer

KM series high-precision hypoid helical bevel gear reducers represent advanced solutions that the current market requires in terms of high efficiency and flexibility. It has the following characteristics:

1. 2-stage or 3-stage helical or hypoid bevel gear set, with a maximum reduction ratio of 7.5 to 300.

2. Hard tooth surface gears have higher gear hardness and strength than NMRV series worm gears. Durable and long lasting.

3. Super energy saving. The efficiency reaches more than 90%. Compared with the NMRV series worm gear reducer, the efficiency is increased by about 10% to 40%.

4. Modular design, diverse combinations

5. Installation dimensions are compatible with NMRV series (except size 050)

6. The high-efficiency KM series can replace the RV series and has a wider range of applications.

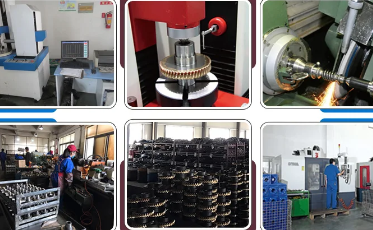

Our Factory

Workers

Services

Years

How Helical Reducer Work

A helical reducer, a type of gear reducer, operates using helical gears which are cut at an angle to the face of the gear. When these gears engage, they create a smoother, more gradual transfer of force than standard spur gears. As the helical teeth engage, the contact starts at one end of the tooth and gradually spreads across the entire tooth, resulting in less noise and vibration than spur gears. The helical design allows for more teeth to be in contact during operation, thereby increasing the load capacity and efficiency of the gear. In the reducer, the helical gears are used to decrease speed and increase torque, effectively transmitting power from a high-speed motor to a slower speed application, making them ideal for applications requiring high precision and smooth operation in industries like automotive, manufacturing, and machinery.

Helical Reducer Application

Helical reducers, known for their efficiency and durability, are utilized in a wide array of applications across various industries. Their unique design, characterized by angled teeth, allows for smoother and quieter operation compared to traditional spur gears. Here are some key applications of helical reducers:

Conveyor Systems

In manufacturing and material handling industries, helical reducers are often used to control the speed and torque of conveyor belts. Their smooth operation is beneficial in transporting delicate or precision items.

Automotive Industry

Helical gears are commonly found in automotive transmissions, where they facilitate smooth gear shifting and reduce noise. They’re essential for ensuring efficient power transfer from the engine to the wheels.

Industrial Machinery

Many machines in industrial settings, such as mixers, grinders, and extruders, use helical reducers to regulate speed and torque, ensuring efficient and consistent operation.

Robotics and Automation

In robotics, helical reducers are favored for their precision and reliability. They are used in robotic arms and other automated systems where controlled motion is crucial.

Textile Industry

The textile industry employs helical reducers in various machinery for spinning, weaving, and processing fabrics. Their smooth operation helps maintain the quality of delicate fabrics.

Packaging Machinery

In packaging lines, helical reducers are used to ensure the smooth and precise operation of machinery, which is essential for the rapid and efficient packaging of products.

FAQ

What are the technical specifications of your helical reducers?

Our helical reducers are available in various ratios, sizes, and horsepower capacities. They are designed to handle specific input speeds, output torques, and operating conditions. We can provide detailed spec sheets for each model.

Can your helical reducers be customized to fit specific applications?

Yes, we offer customization options for our helical reducers. Depending on your application, we can adjust gear ratios, shaft configurations, mounting options, and material choices to meet your specific needs.

What materials are used in the construction of your reducers, and how do they enhance performance and durability?

We use high-quality materials such as hardened steel for gears and robust cast iron or aluminum for the housing. These materials ensure optimal performance, high durability, and resistance to wear and environmental factors.

How do you ensure the quality and reliability of your products?

Our products undergo rigorous quality control processes including material inspection, precision machining, and performance testing. We adhere to international quality standards to ensure reliability and longevity of our helical reducers.

Get Your Free Quote

Contact Us

Our customers’ commitment to your specific use case:

Outstanding expertise for optimal performance and reliability

best cost-benefit ratio

Short response times and high product availability

Address

Bv. Saenz Peña 1975 – San Francisco

Córdoba – Argentina

Phone

+549 3564 676704